Insights from the AAR Tank Car Committee

This April the Association of American Railroads held their annual Tank Car Committee meeting in Oklahoma City. AITX has been proud to be an active participant in this steering committee for over 30 years.

Roger Dalske, our Vice President of Regulatory Operations, was in attendance.

It was great to be back in-person with this highly qualified group of experts. Per usual, there was a full agenda of topics, discussion, vocal opinions, and actions. We thought it would be insightful to pass on a sample of three of the relevant topics and announcements discussed this year so you can stay knowledgeable and proactive with industry policies.

Repair facilities to seek approval from service equipment owners when taking on shop work.

According to a recent audit by the Federal Railroad Administration (“FRA”), often the entity requesting tank car repair work is not the service equipment owner responsible to the Department of Transportation (“DOT”), rather a lessee or a fleet manger. It is the responsibility of the car owner to do an analysis to determine the proper interval that will be stenciled on the car. And, the responsibility of the repair facility to make sure that there is communication and approval about service programs from the actual car owner. This has been flagged as an area of importance to the FRA, and one they plan to continue to enforce.

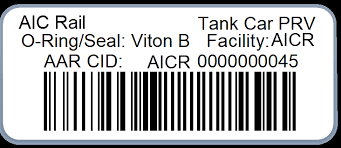

All pressure relief values need an AAR Component Identification (“CID”) tag.

It is important to the AAR that all pressure relief valves have a CID tag, so they can quickly identify cars that would be subject to a recall if a defective valve or facility is to be identified. If the system is operating correctly, every pressure relief value that’s registered with a CID tag should be associated to a car. However, it’s being reported that there are more pressure relief values registered by facilities manufacturing or maintaining values than the actual number of valves associated with cars. Owners and facilities are encouraged to ensure that when pressure relief valves are applied, they are properly associated to the car with a CID tag.

Welcome the new “MxV Rail” — the leading team in rail research, testing, and technology.

MxV Rail — formerly Transportation Technology Center, Inc. (“TTCI”) — is a wholly-owned subsidiary of the AAR with a team of more than 300 employees chartered to advance the scientific research of railroads focused on improving rail safety, reliability and efficiency. The new name, MxV, is the equation for momentum and, hopefully, a sign of what to expect from this group. This introduction is the result of the AAR no longer having a contract to run the federally-owned TTC facility after a nearly 40-year relationship. The AAR is using this as an opportunity to pave a new path by opening a new facility in Pueblo, CO this Fall. Some of the slated improvements will be a high tonnage loop for accelerated service testing, curve negotiation loops, and additional track infrastructure to support AAR certification testing for freight car customers.