Planning your Tank Qualification Strategy

Tank cars are the workhorse of North American rail freight. From 1995-2021, there was over 370k North American tank car deliveries*. That’s a lot of industries, companies, customers, and shipments… DOT-111s, 117s, 211s, or 112s… new builds and retrofits.

A lot of what we all use every day comes by tanks. 75% of tanks car are hazmat shipments which will be our energy fluids (crude, propane, LGP, diesel, butane) and other flammable (alcohols) and non-flammable chemicals (sodium hydroxide, hydrochloric acids). The other 25% ranges across liquid food oils (corn syrup, soybean, rapeseed, and vegetable oil) to farming and construction by-products (nitrogen fertilizer, clay and limestone slurry)*.

Whether you lease or own your cars, it’s hard to miss a day without some kind of tank qualification discussion. Due to the cyclical uptick of crude between 2012 and 2015, there are a lot of cars in circulation that are nearing their qualification intervals, with estimates of roughly 30% of tanks due in the next three years*.

If you have a big fleet with different aged car-types, there is much to consider when planning and scheduling your qualifications to maximize uptime and shipping lanes while also alleviating internal stress with your logistics team.

We chatted with our tank experts on our fleet management team:

* Larry Culligan (Fleet Management, Director)

* Jacob Leffel (Fleet Management, Manager)

Here are some tips to best approach your tank qualifications planning.

- Source: RSI, Tank Car Resource Center

Have a mid-term and long-term tank qualification “Shopping Plan”

When Larry and Jacob talk to fleet managers, the number one insight they notice is that there are many external factors beyond when your individual tank cars are up for qualifications. Smart fleet managers triangulate their regulatory obligations with the downtime cycles of their fleet, their production demand pipeline, and larger market trends. We generally recommend a strategy with both a long-term fleet plan and mid-term pipeline plan.

A long-term fleet plan takes a view of when all cars are due for qualifications so you do not get too many cars are off-track at once. Qualification dates range based on historical commodity demand cycles or timing of new build production. Some years have high volume, like the next few, and others may have a slowdown. The best plan is to smooth-out qualifications with a steady, predicable flow each year, even if some qualifications are early. A good rule of thumb is to have a forward-looking, ten-year approach that can be adjusted according to internal demand forecasting.

A mid-term pipeline plan is more internal-focused, assessing unit forecasting and the seasonal calendar against qualification deadlines in order to gauge when you are able to release cars, how many you can afford to have in-shop, and for what time frame they can be off-track. Identifying constraints brings active clarity to a hypothetical availability window for when you engage repair facilities with you shopping plan.

We recommend starting early to proactively identify options and reserve space in the proximity of your car route and within your available timeline.

We found it’s helpful to do this analysis not only to book slots but also start an active internal evangelism effort. It is important for other team members in-and-out of the rail logistics team to anticipate the issues and disruptions that come with this busy qualification season.

The more education and preparation, the better teams are ready to be flexible and opportunistic. Just as we mentioned in our Resizing your Fleet post, this may mean having an overage plan over the next five years to have access to extra capacity. Fleet managers are seeing delays across the railroad due to service reliability and congestion. Many repair shops have a qualification queue due to the current levels of need. You do not want qualification backlogs to interfere with running your business successfully.

Pinpoint the right repair shops on your fleet’s route that meet your quality-standard.

Once you have a good understanding of which cars should be prioritized and when, it is preferred to have a hit-list of repair shops to engage.

Work with a shop you know and trust. One that’s located on your freight route, who knows your cars and commodities, and has a quantifiable record of quality, safety, and timeliness.

The most important factor is to identify facilities that have tank car qualification experience, including certification through the AAR (Activity Code B81) and a compliant program with the Federal Regulations (49 CFR 180.509).

When talking with prospective shops, ask about their team, training, and ongoing education process. Below is a sampling of topics to ask which are integral to the quality of program:

* Visual Inspection

* Structural Integrity Inspection

* Thickness Test

* Safety Systems Test

* Leakage Pressure Test

* Internal Coating and Lining Repairs

* Service Equipment

* Safety Plan and Record

It’s important to ensure your repair partner has a plan for all of these to complete your qualifications in a safe and timely manner.

Often qualifications can be the firs step of additional repair work, so make sure that can be done at the level of quality and cost you expect. Full transparency upfront is crucial to stay on-budget and on-plan.

Evaluate what AITX offers to see if it meets your Tank Qualification needs

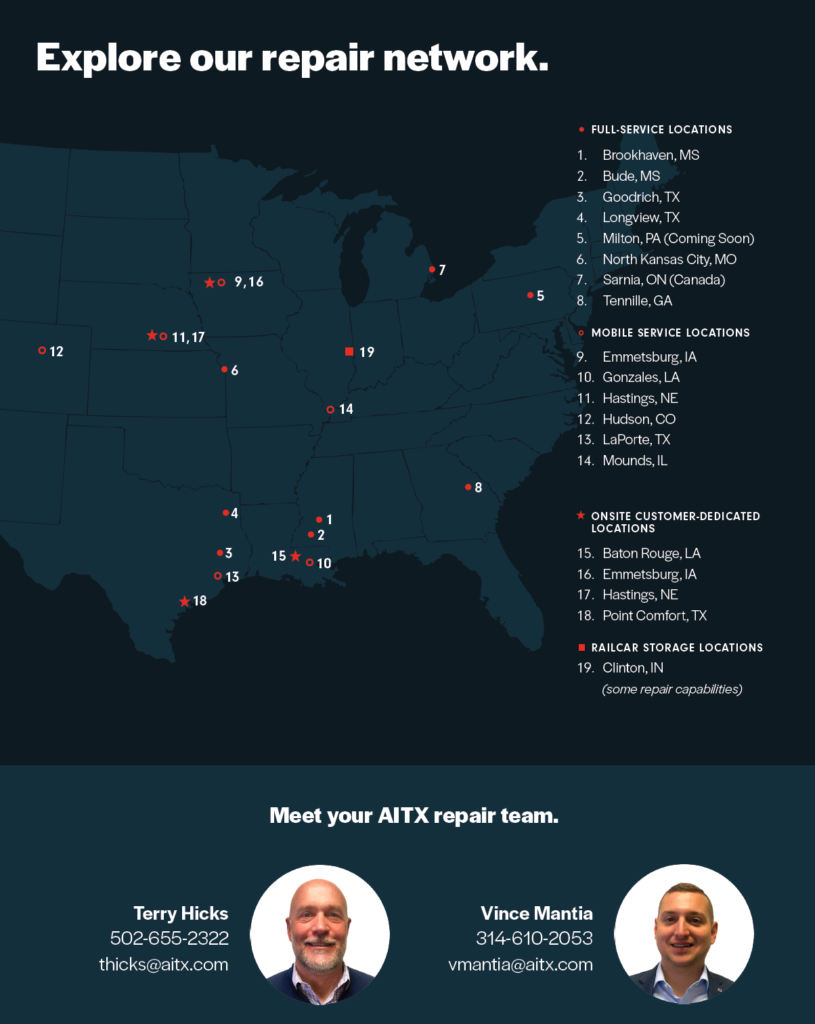

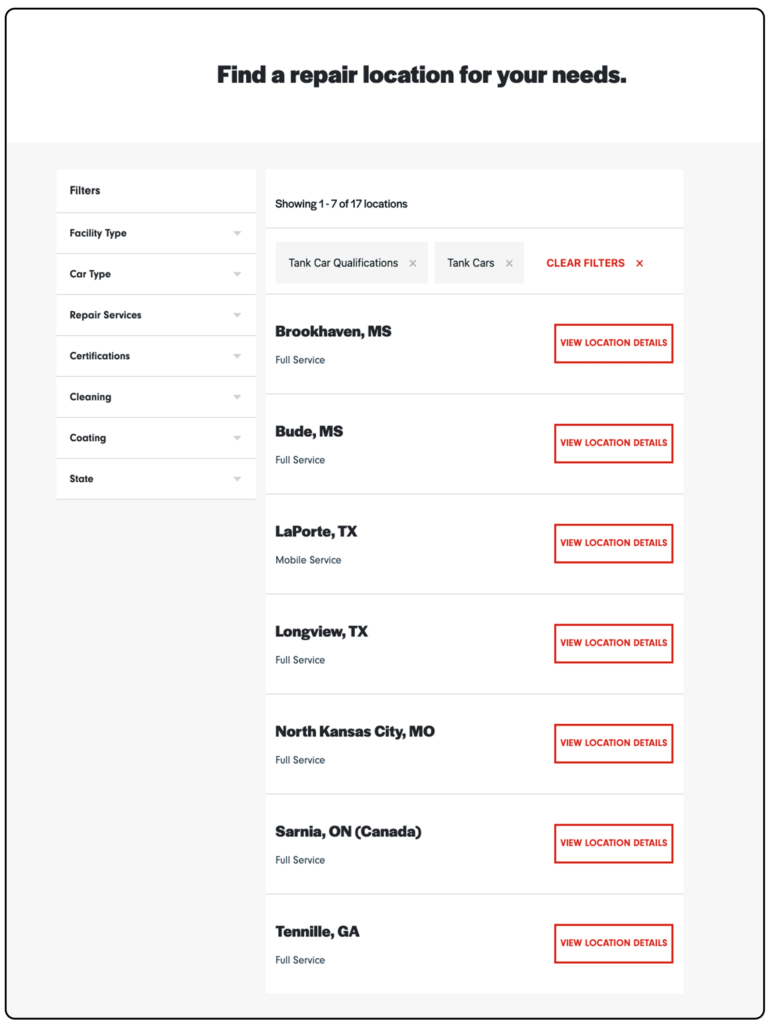

AITX has a network of 17 facilities across full-service, mobile, and customer onsite. You can match your needs with an AITX location via our Repair Search Tool.

There are seven facilities that offer Tank Qualifications.

* We have three locations on the CN line. North in Canada is our AITX Sarnia (Ontario) facility which is a full-service shop with 240 car capacity. South on the line in Mississippi we have AITX Bude and AITX Brookhaven. This month we did a Bude Spotlight to learn more. Last year we announced a Brookhaven expansion to invest in the region and our overall tank car capabilities.

* We also have two locations on the UP line both in Texas. In Northeast Texas, we have our AITX Longview facility which has a 230 car capacity. South on the line we have our AITX La Porte mobile unit on the Gulf which has full repair and maintenance capabilities including the ability to do tank qualifications.

* Our AITX North Kansas City facility is on the BNSF but has intersect with five of the Class 1 rail lines (Canadian Pacific, Kansas City Southern, Norfolk Southern, and Union Pacific). See our AITX NKC Spotlight.

* Our AITX Tennille (Georgia) facility is on the NS line with a 200 car capacity.

Our teams are expert tank engineers, seasoned in qualifications, mechanical repairs, and welding with full-maintenance services across cleaning, coating, and painting. AITX is a board member of the AAR Tank Car Committee and at the table for industry standards and regulations.

Below you can review our full repair map and our sites that specialize in tank qualifications. If you want more information on our services and availability, feel free to reach out to Bruz Hicks or Vince Mantia from our team.

Our fleet management brain trust in discussion on the tank qualification planning issues and ideas.